Definition of flotation

Selective flotation of hydrophobic minerals and their separation from hydrophilic minerals is called flotation. This action will increase the grade and, as a result, increase the purity of the mineral extracted from the product. In order to increase the grade of elements in the purification process, flotation should be used.

The process of carrying out the process of flotation

In the flotation operation, the differences in physical and chemical surface properties of minerals are used. And the act of separation is done. In this method, the minerals are crushed to suitable dimensions and when they are mixed with water. They are soaked or remain suspended on the water. Valuable minerals such as talc, coal, diamond, graphite and molybdenite cannot be soaked and immersed in water. These types of minerals are called hydrophobic or hydrophobic. In the whole surface of most minerals, it is heated in contact with water. These materials are called hydrophilic or hydrophilic.

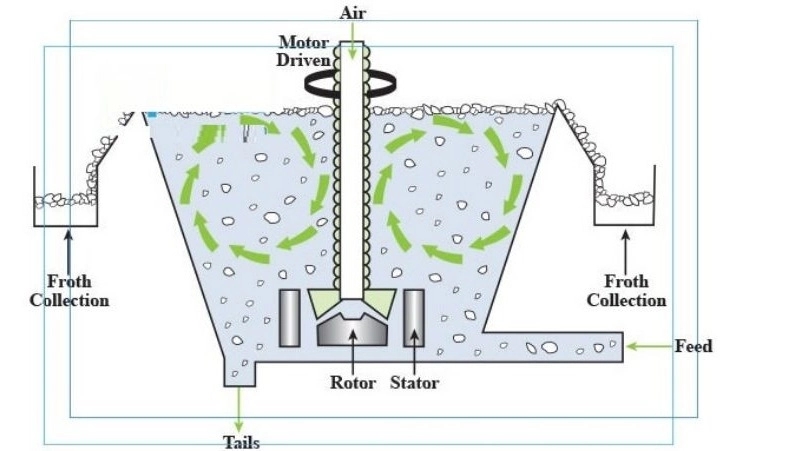

When the valuable mineral is not hydrophobic, to make that mineral hydrophobic. They use chemicals that are called collectors. This stage in which the preparation is done is called conditioning. In this case, the collectors increase the tendency of the particles towards the air. In flotation, chemical substances are used that make the activity of flotation completely optional. And the miner can adjust them based on valuable minerals and tailings. In all stages of preparation and flotation, in order to prevent the settling of the solid phase and to increase the kinetics of the processes, the pulp is stirred by a stirring device.